Internal R&D – the burnt stripe effect

Extended material is available – AMPERE 2009 presentation on the burnt stripe effect – IMPI 2007 presentation on “puddles and droplets”.

The

so-called cold rim effect is strong for thin semidry loads

with

radii less than about 35 mm (at 2450 MHz), which thus get a centre

heating that cannot be modified much by the design of the microwave

heating system. But a particular amplification of the heating in a

typical narrow zone across the diameter in load items such as potato

chips may also occur – see the picture below to the left.

If

there would be only

drying-out by the microwave energy, this would be faster in the whole

central region. Since the permittivity then decreases and by that the

absorption capability of these dryer parts, a negative feedback would

then occur and even out the drying. But as is seen in the photo to the

left, the burnt stripe effect is indeed a runaway phenomenon,

where an already dried-out region absorbs additional power so burn

marks are created. It is

concluded that liquid water transport is necessary for the effect to

occur.

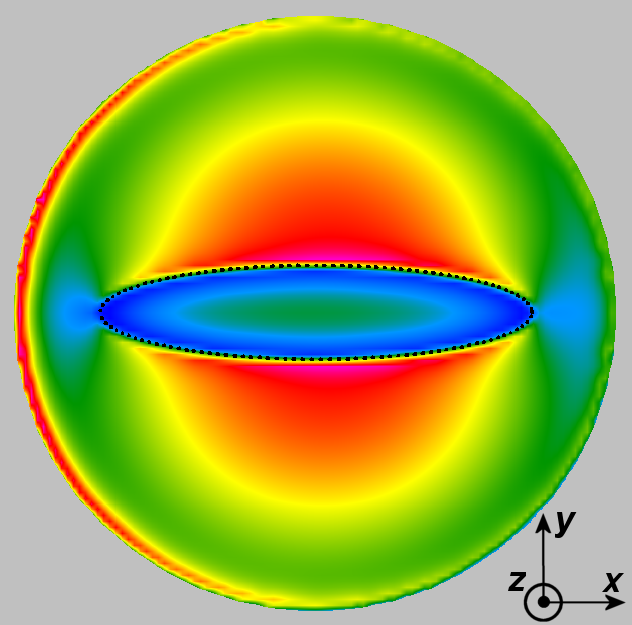

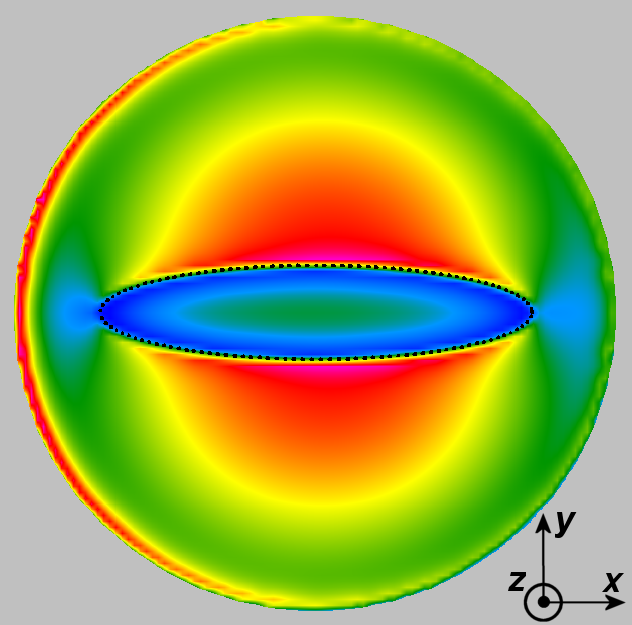

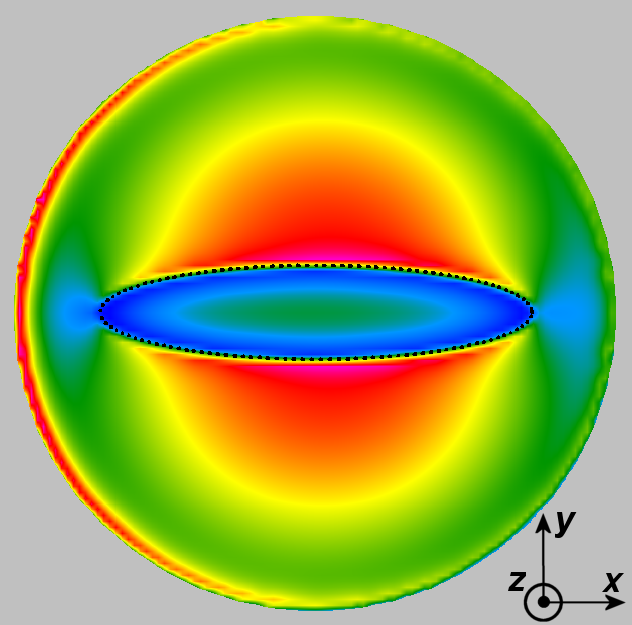

What

happens is illustrated in the numerical modelling scenario in the image

to the right. This shows a circular 24 mm diameter thin potato chip at

100 °C (permittivity ε = 50–j16

) having an elliptical inclusion with axes 18 and

4 mm, representing a partially depleted region (permittivity ε = 8–j1,6). This region is marked

with a black dotted curve. The potato chip is irradiated from the left with a free

space TM-polarised 2450 MHz wave with incidence angle θ = 82°. The

magnetic source field is thus y-directed

and the main current

x-directed;

the dominating electric field is z-directed.

The following phenomena can be distiguished:

- There

is a heating (and thus current) concentration in the high-ε part close

to the low-ε area. One can explain this as being due to the current

following the shortest path with high ε and thus "avoiding" the low-ε area. The

boundary is concave and not convex as is the case with the cold rim

effect, so conditions are now reversed.

- There is a significant heating in the centre region

of the low-ε area.

This is due to direct action by the strong external z-directed

electric field. The phenomenon is

amplified by the fact that the load is thin. It is to be noted that the

heating intensity in the centre is quite strong: almost half of the maximum in

the non-depleted area, in spite of the ε″ being ten times lower and

the penetration depth being

more than three times larger than in the non-dried region. This power

density will indeed cause overheating, in consideration of the limited amount of remaining water for evaporative cooling in this semidry region.

- There is a significant heating intensity minimum

just inside the low-ε area

boundary. This is a result of the z-directed

electric field being almost short-circuited there, by the high-ε

area nearby. One can also explain the minimum as a so-called magnetic wall

effect. The minimum intensity is less than half of that in the centre

of the low-ε area.

These

sharp heating gradients result in the boundary between the outer

relatively moist and the inner dry regions to become relatively

constant, while the inner region continues to dry out. The resulting

narrow burnt regions are clearly seen in the photo to the left.

Can

this effect of uneven heating be avoided? Load rotation or changes of

the polarisation of the TM field will not help much; the inner

overheated region will

then instead become symmetrically circular. The use of other microwave

polarisations will result in edge overheating as well as a risk of

lower microwave system efficiency. There are no easy solutions.